CIPP

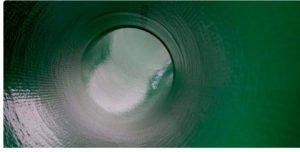

is used to rehabilitate existing sewer pipelines by lining the walls of the existing pipe with an epoxy resin tube.

Rescue Rod’s CIPP Liner is a “no dig” sewer rehabilitation system for repairing damaged drains and sewers without the need to carry out disruptive excavations.

Developed specifically for the rehabilitation of pipes in diameters from dn 50 to dn 250 and offers many advantages compared to traditional rehabilitation.

Advantages

- Rapid rehabilitation without excavation, dirt and noise.

- Up to 50% cheaper than open construction.

- Suitable for almost all damage and all pipe materials.

- Durability of over 50 years.

Eco-Friendly Pipe Relining Choice

FEATURED CASE STUDY – CIPP LINER

Dairy products plant seeks solution to cracks in clay pipe

Dairy products plant seeks solution to cracks in clay pipe

Project Objectives:

Project Outcomes:

Project Outcomes:

Four sections were under taken of 20m x 150mm Diameter clay pipes relined, totallying 80 meters.

12 x laterals were reinstated with the use of the Picote Maxi Miller.

Project:

Internal pipeline inspection and Hp cleaning was carried out before the lining process begun to ensure pipes had no major defects and that CIPP was the best option for the project.

The Inversion Method :

Compressed air to push the liner into the receiving pipe. One end of the liner is attached to a collar-like device at the insertion manhole/pipe. As air is introduced, the fluid “pushes” the liner to the next manhole/end point. As it advances, the liner is turned inside out; this action is the genesis of the process’ name. When the liner protrudes into both manholes/end point, it is trimmed, secured at each end, and inflated against the receiving pipe.

Once the liner is in place, it is cured, transforming the flexible liner into a rigid new pipe within the original pipe, pressurized ambient air was the primary curing method. The process is selected based on the liner material, the resin and its chemical properties, and pipe diameter.

Success Criteria:

Click Here to view the entire project.

|

|

|

.jpeg)

WhatsApp us

WhatsApp us