Rescue Rod has recently added some new equipment to further increase our range of services.

1. Kaiser Combination unit

In order to keep up with our clients demands Rescue Rod has added another jetting and vacuum combo unit to our fleet. This new addition brings us to a total of 10 of the ultimate drain cleaning machines available. These units are capable of efficiently recycling water, vacuumed up from the drain, and using it for jetting. The powerful vacuum system can also be used for sucking up sludge, solids and liquids which can then be safely disposed of at a suitable disposal site. See more here

2. Pipe bursting

Pipe bursting is done by placing a hydraulic rod pushing unit in a start pit at one end of the pipe being replaced. A string of steel rods is then passed through the pipeline to a reception pit at the other end of the bursting run. A bursting head is then attached to the rod string, followed by an expansion cone, a swivel and finally the replacement pipe. Once the assembly is completed the hydraulic rod unit is used to pull the rod string back towards the start pit. This causes the bursting head and the rest of the assembly to be pulled through the pipeline. The bursting head breaks the pipe up, the expansion head pushes the shards into the surrounding ground and the new pipe is pulled into place in the void created.

Ductile pipes need a pipe splitter. Using exactly the same rod pushing/pulling rigs as for standard pipe bursting, the same technique is followed but with the splitter head instead of the bursting head. The splitter head works by first scoring the inside of the pipe being replaced, something like when glass is cut. A follow-up blade then slices through the split in the now weakened pipe, tearing it open. The expansion cone, instead of pushing shards into the surrounding ground, in this instance, forces the now split pipe apart to create the necessary void. The new pipe is pulled into the space created.

3. CIPP lining

A resin saturated lining tube is installed in a pipeline by inverting the tube with air pressure. Once the tube is in place the resin is usually heated to induce a chemical catalyst or hardener to set off the curing process. The curing process is usually by hot water, while ambient curing can be used for smaller diameter renovation projects e.g. house drain connections to sewers.

Application

CIPP Lining techniques can be used to renovate most gravity pipelines and culverts and pressure pipelines used for utility services such as water, sewage and gas as well as other process effluent pipelines e.g. food and drink industries; oil and gas etc. Rescue Rod is able to line circular pipes from 50mm to 200mm diameter. To install a CIPP liner, inflation or inversion techniques using air or water pressure may be used.

The installation length can vary from short sections over a joint or defect for a localised repair to full length linings typically 15m to 50m.

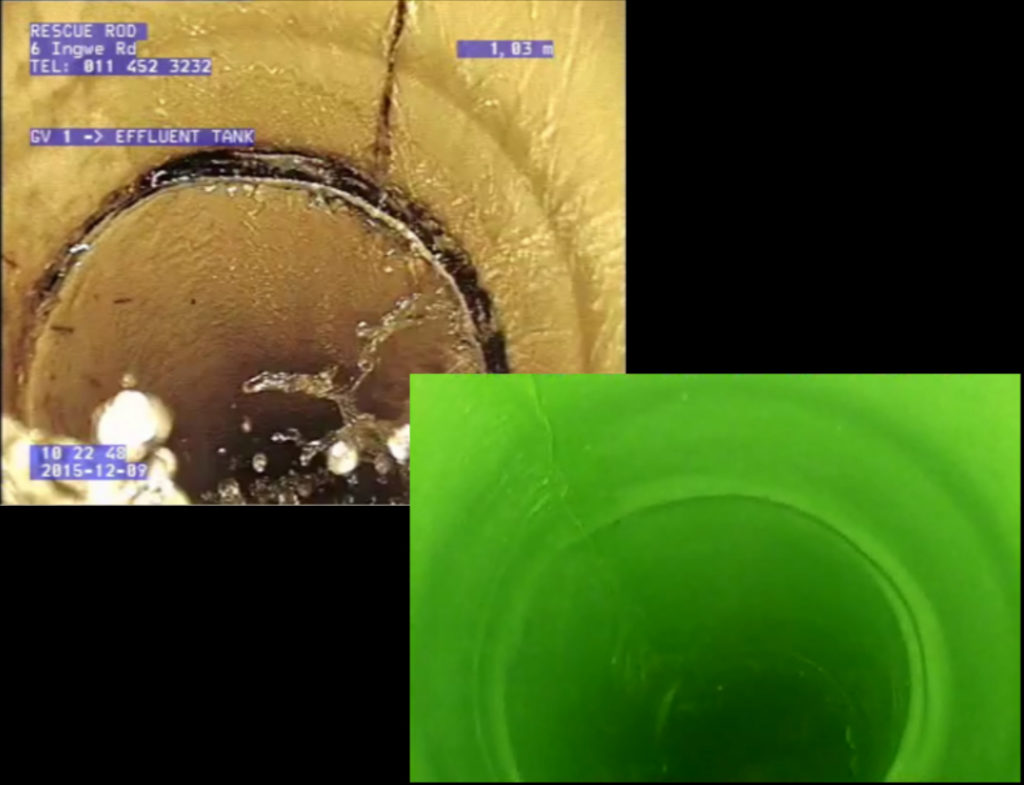

200mm PVC pipe with an open joint – before and after lining

4. 22000 litre water tanker

Due to increasing water supply interruptions Rescue Rod saw the need to acquire a larger capacity tanker. Although the 8000 litre tankers are sufficient for most smaller premises the larger tanker saves valuable travel time especially when it comes to hospitals, busy hotels and casinos.

Our water tankers only transport fresh drinking water!

22000l Water Tanke

5. Maxi milling machine

The Maxi miller is a tool used mainly for reinstating connections after relining pipes, however with a range of different cutting tools available the machine can be used for cutting away intruding connections, root removal, scale / rust removal and removing weld beads in HDPE pipes.

WhatsApp us

WhatsApp us