Pressure Pipe Rehabilitation

Benefit from:

- Cost saving of up to 40%

- Long Insertion Lengths of up to 2500 meters

- Ability to Negotiate bends of up to 45 degrees

- Quick rehabilitation with up to 400 metres per hour

- Protection against corrosion

- Small construction sites with low intervention in the environment

Khuduyane Quigley / Rescue Rod – Projects

Water Liner Installation – City Deep May 2017 – Water

The installation of the Primus Liner was performed and due to the flexibility of the liner, the installation of the Primus Liner could be achieved within a period of only 10 minutes.

Transported: Potable Water

Host Pipe Diameter: DN 160mm

Host Pipe Material: Steel

Operating Pressure: 16 bar, test pressure: 20 bar

Primus Line® System: DN 160

Total Length: 80 m

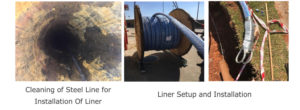

Sasol Secunda Fire Water Pilot Project – Refinery Main Fire Hydrant Water Supply

Client problem and challenges:

Client problem and challenges:

Solution:

Project details:

Sections: 2

Diameters: DN250 DN400

Total Meters: DN250 35m DN400 84m

Installation time 6 working days including cleaning and pipeline inspections.

ATE Boksburg Primus Line Drinking and Sprinkler Water Rehabilitation

Client problem and challenges:

Client problem and challenges:

The main pipeline water supply at ATE was found to lose between 20-30000 litres of water per night due to numerous pinhole leaks and the pipe being more than 40 years old and in a very bad overall condition.

The pipeline is running from the main factory gate under the truck weighbridge for 44m turning right at a 45 degrees angle for 15m then left at 30 degree angle toward the factory for 16m.

Excavating to replace and installing a new pipeline would have meant days possibly weeks of no water and the added expenses of new pipeline, excavation, installation times etc.

Solution:

Rescue Rod Pty Ltd presented to the Client the new Primus Line technology which can rehabilitate a pipeline without obstructing the busy factory traffic, the collecting and deliveries from the warehouse and the weighbridge usage. Primus Line is apart from other technologies as the liner can be used in a pipeline with bends and with quick insertion times and fast re-commissioning. Added to the surface known challenges when exposed the water pipeline was next to and very close to storm water pipelines which added to space restrictions and confirmed that the best solution was lining with Primus Line and not installing a new pipeline.

Project details:

Total Meters: 75m with 2 bends. Liner diameter: 150mm

Installation time 3 working days due to client requirements with regards to access of the trucks in the driveway.

WhatsApp us

WhatsApp us