Pipeline rehabilitation can be defined as “a family of methods, materials, and equipment capable of being used for the installation of new or replacement or rehabilitation of existing underground infrastructure with minimal disruption to surface traffic, business, and other activities.”

The various applications used by Rescue Rod can be seen listed below – click on an application to read more about it.

During the renovation process, the liner is soaked in resin and then inserted into the defective pipe using pressurised air or water. This completely lines the inside of the pipe and eliminates any existing or potential damage.

Curing creates a completely new, watertight pipe within the old one.

This rehabilitation application can be carried out quickly, permanently and cost-effectively.

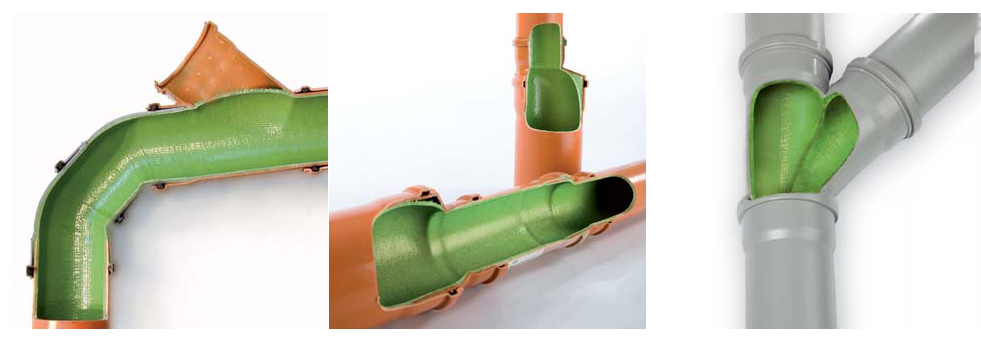

BRAWOLINER® which is a “no dig” sewer rehabilitation system for repairing damaged drains and sewers without the need to carry out disruptive excavations.

The BRAWOLINER® process was developed specifically for the rehabilitation of pipes in diameters from dn 50 to dn 250 and offers many advantages compared to traditional remediation.

Advantages

- Rapid rehabilitation without excavation, dirt and noise

- Up to 50% cheaper than open construction

- Suitable for almost all damage and all pipe materials

- Durability of over 50 years

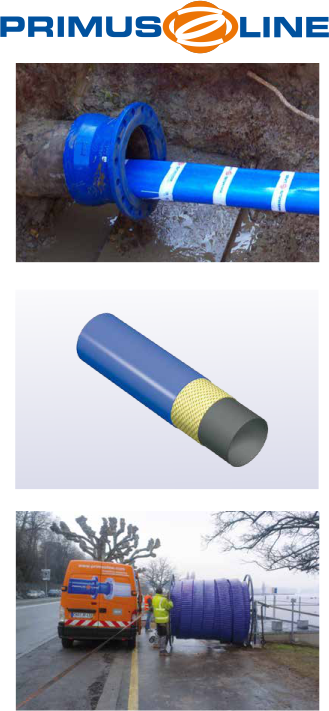

Primus Line® Trenchless Pipe Rehabilitation Technology

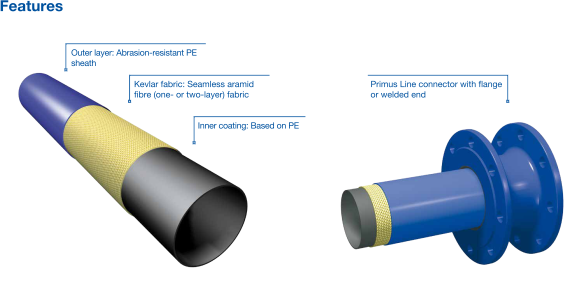

Is an innovative technology for the trenchless rehabilitation of pressure pipelines for different media such as water, gas and oil. The process is based on a flexible high-pressure hose and a connecting technology, which has been developed specifically for this system.

Primus Line® is suitable for the transportation of various liquids in the field of water, and holds drinking water permits in several countries.

The extremely smooth inner coating, ideal flow characteristics and the optimized systems for high-, medium- and low-pressure requirements all make Primus Line® an economical choice for the rehabilitation of aging pipelines. Water authorities and network operators benefit from a sustainable and reliable operation and consistent revenue.

Easy to Use

-

- Reduced use of machinery

-

- Up to 6,000 m can be supplied on a transport drum

-

- Short construction period due to large insertion lengths

-

- Small pits, reduction of roadworks

-

- Able to negotiate bends

-

- Insertion through bends of up to 45°

-

- Fast recommissioning

High Strength and Quality

-

- Life span of at least 50 years

-

- High abrasion and cut resistance of the outer coating

-

- No corrosion of Primus Line®

-

- Certifications in the field of drinking water

High Performance

-

- Minimum cross-section loss due to low wall thicknesses of 6.0 or 8.0 mm

-

- Improved flow properties of the pipe

Quicklock Sewer Rehab Sleeve Restores Structural Strength, Seals Out Infiltration

Target Failing Pipes with a Stainless Rehab Sleeve that Installs in Minutes.

With more than 1,000,000 units installed worldwide, Quick-Lock provides structural trenchless pipe repair with heavy-gauge 316L stainless steel, plus infiltration abatement with an EPDM rubber gasket. It installs in minutes with two people and minimal overhead. Suitable for sanitary sewers, water lines and industrial pipes, Quick-Lock solves:

• Infiltration

• Longitudinal Cracks

• Circumferential Cracks

• Holes

• Offset Joints

• Abandoned Laterals

• Root Intrusion

Quick-Lock is positioned inside the host pipe on a wheeled flow-through packer pushed by any standard CCTV crawler. Once in position, air pressure supplied to the packer expands the sleeve against the pipe wall. Patented stainless gear ratchets within the sleeve sustain the outward pressure, which structurally reinforces failing regions of the host pipe, and also compresses the gasket for leak-proof service. Compared to open digging and CIPP point repairs, Quick-Lock eliminates:

• Digging and backhoes

• Resin

• Wet-out

• Pot life

• Cure

• Bypass pumping

• Wash-outs

Point Repair: For standalone point repair, or for pre-lining under high infiltration, Quick-Lock sleeves restore a pipe’s structural integrity and seal out groundwater. They minimize diameter loss and outlast any other rehab.

Please Read our article New to Rescue Rod – The Quicklock System for more information

Technical Data

-

-

- Outstanding bonding properties to most materials

- Resistance to 63+ chemicals and oils

- Non-flammable, making it ideal for hotels, airports, hospitals, etc.

- Non-hazardous, so no transport or disposal problems

- Resin cures in the presence of water

- Structural properties exceed the minimum requirements of ASTM F 1216

-

Environmentally Safe

-

-

- PipePatch contains no VOCs or Styrenes

- Safe for storm and sanitary sewers

- PipePatch resin does not get hot

- Maximum temperature may reach 105º F

- Safe to touch

-

Application Advantages

-

- Available to repair 2” – 24” diameter pipe in 24” and 48” lengths

- Flow-thru packers prevent backups during repairs

- No more costly, disruptive and time consuming excavations

- No more road closures or traffic back ups during repairs

- Only standard sewer cleaning and inspection equipment required

- Small repair crews – as few as 1 to 3 people

- Short repair times – several can be done in one day

- Field tested for over 10 years with a durable 50 year repair life

WhatsApp us

WhatsApp us